One of concerns in these days is environmental issue. We may say the serious subject would be occurred with factors such as air pollution, water pollution, or soil pollution and these pollutions, leading leakage of inside liquids from piping.

We had developed Green Cover as a solution to the subjects instead of existing solution such as duplex tube.

Main futures of Green Cover are as follow ;

- ① Convenience ; Available to every kind piping on not only new-built area but also existing area.

- ② Easy application : Adoption of Zipper system

- ③ Easy confirmation to leakage condition : Adoption of transparent film

- ④ Reliability : Protection of inside liquid leakage with installation components

We can say duplex tube system does not have the above features.

Furthermore one of film materials, Type A, made of fluorine resin, bears acid, alkali, and other solvents and also have superior weather resistance. Then it is available to many kinds of operating conditions.

Application area

- Chemical plant, Semi-conductor plant, Oil refinery, Thermal power plant, nuclear power plant and relative facilities, display manufacturing plant, etc.

- Main purposes of using Green Cover are reduction of air pollution and water contamination due to protection of inside liquids leakage and splashing from piping system such aa chemical agents, oil, pure water, ultrapure water, etc.

- The application is available to almost all piping and the components such as flange, elbow, thee, socket, valve, gauges, etc. on not only new-build piping or but also existing piping.

- The application is also available to protection of rainwater penetration on outdoors piping, salt damage, etc.

- Drain of leaked liquid is available by using optional components.

Main features

- Green Cover is composed of transparent resin film, having weather resistance and chemical proof, and zipper welded to the film, whose material is the same one. Then it is available in almost all requested shapes.

- The transparent film is thin and flexible. Then Green Cover is also available in application to existing piping due to the above structure.

- By assembling packing and other optional components, rainwater penetration in outdoor use, and leakage and splashing in vertical piping are prevented. In this case, sealing on fastening of zipper is needed.

- Over 5 years life to deterioration and discoloration of material is available except for external factors. As to Type A, we have achievement of over 10 years life in outdoor use.

- Application temperature range : Type A ; -50℃ ~ 150℃, Type B (Polyethylene) ; -30℃~ 60℃

The film is flexible and thin. Then it can absorb expansion of piping with temperature change range. - Green Cover bears outburst pressure, 1000mmAq to 2000mmAq, but pressure proof range to dripping leakage by internal pressure is 400mmAq to 600mmAq.

- You don’t need any special tools, ability, and experience for installation and remove.

- Optional components of drain adaptors including cock, hose, etc. are available.

Installation samples

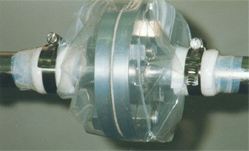

- Flange

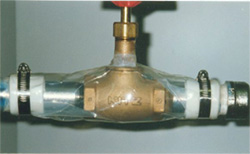

- Valve

- Drain assembled

- Elbow

- Elbow connected by sockets

- Elbow connected by flanges

- Tee connected by sockets

- Tee connected by flanges

Form and dimensions of Green Cover

Standard size range is 15A (1/2B) to 300A(12B). Bigger or smaller size is available upon your requests.

Standard size range is 15A (1/2B) to 300A(12B). Bigger or smaller size is available upon your requests. We can of course accept standard form to piping and almost all piping components. Special shape and combination shape are also acceptable.

We can of course accept standard form to piping and almost all piping components. Special shape and combination shape are also acceptable. In the case of big size, complex shape, combination of some piping and components, and unavailability of fixing band due to the complex shape, please contact us.

In the case of big size, complex shape, combination of some piping and components, and unavailability of fixing band due to the complex shape, please contact us. We may ask you of presentation of drawing on piping and connected components for our quotation or design.

We may ask you of presentation of drawing on piping and connected components for our quotation or design.

Samples of Green Cover form

Characteristics of film material

Type A : Transparent fluorine resin film

Type B : Transparent polyethylene film

| Characteristics | Type "A" | Type "B" |

|---|---|---|

| Material | Fluorine resin | Polyethpren |

| Appearance | Transparent | Transparent |

| Thickness (mm) | 0.15 or 0.3 | 0.3 |

| Gravity | 1.78 | 0.90~0.95 |

| Tensile strength (kgf/cm2) | 230~315 | - |

| Elongation (%) | 480~500 | - |

| Tear strength (kgf/cm) | 110~120 | - |

| Oxygen permeability coefficient (c.c.・mm/m2・24h、atm.) |

27 | - |

| Oxygen index | 54 | - |

| Melting point (℃) | 162~165 | 80~120 |

| Heat decomposition temperature (℃) | 380 | - |

| High-temperature use limit (℃) | 120 ~150 | 60~70 |

| Low-temperature use limit (℃) (Embrittlement Temperature) |

-55 | -30~-15 |

Weather Proof

Type "A"

| Time | Tensile strength retention | Elongation retention | 100% modulus retention |

|---|---|---|---|

| 1000Hr | 96% | 102% | 99% |

| 2000Hr | 96% | 104% | 102% |

| 5000Hr | 90% | 98% | 103% |

Test method : Accelerating test by Sunshine Carbon Weather Meter

※Note:The above test for 300 hours is considered 1 year exposure outdoors

Type "B"

Using limit in outdoors is considered 1 to 2 years based on exposure outdoors test results

Chemical proof

| Chemical | Type "A" | Type "B" |

|---|---|---|

| Hydrochloric acid in 35% | ◎ | 22%〇 |

| Sulfuric acid in 97% | ◎ | 98%△ |

| Nitric acid in 70% | ◎ | 95%△ |

| Phosphoric acid | ◎ | 30%◎ |

| Hydrofluoric acid in 50% | ◎ | 50%◎ |

| Sodium hypochlorite in 10% | ◎ | 〇 |

| Ammonia water in 30% | △ | 〇 |

| Ethanol | ◎ | 40%〇 |

| Toluene | △ | × |

| Methyl Ethyl Ketone | × | × |

| Glacial Acetic Acid | × | × |

| n-Hexane | ◎ | - |

Weight gain rate : Dipping in room temperature

◎:Less than 5% 〇:From 5% to 10% exclusive △:Form 10% to 20% exclusive ×:20% or more

Standard Size

| Nominal dia.(A) | 15A | 20A | 25A | 32A | 40A | 50A | 65A | 80A | 100A | 125A | 150A | 200A | 250A | 300A |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal dia.(B) | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| Outside dia. of pipe(O)mm | 21.7 | 27.2 | 34.0 | 42.7 | 48.6 | 60.5 | 76.3 | 89.1 | 114.3 | 139.8 | 165.2 | 216.3 | 267.4 | 318.5 |

| Bore dia. of Green Cover(O)mm | 38 | 38 | 45 | 53 | 60 | 75 | 87 | 100 | 125 | 151 | 176 | 227 | 279 | 330 |

Installation Components

It is possible to prevent leakage from cover and penetration of rain water from outside by using the following components on installation works.

The necessary qty. depends on form of Green Cover, size, and qty. Then we will offer suitable qty. to you.

Installation components

| Code No. | Name | Sepc. |

|---|---|---|

| PSS-2355 | Silicon sponge packing | t2.0 ×35w×5M/ roll |

| TTG-2510 | Teflon adhesive tape | t0.08×25w×10M/roll |

| GSS-135 | Silicon adhesive | 135ml / tube |

| SUS Band | SUS Band fastened with thread | Selected due to size |

Details of drainage adaptor (Unit : mm)

- DH-8

- DH-18

- DL1/4

- DL-H12

- DL25A

①Adaptor ②Nut ③Packing

Procedure of quotation or order

Please let us know the following subjects for quotation or order

Connection spec. of piping : Flange, Butt welding, Socket, Thread socket, Ferrule, Clamp, etc.

Connection spec. of piping : Flange, Butt welding, Socket, Thread socket, Ferrule, Clamp, etc.

Pipe spec. : Size and material ( Metal, Resin, with lining etc.)

In the case of covered with insulator, please let us know outside dia. of the insulator. In the case of valve, Flexible hose, Expansion joint, etc., please present drawing of them including connecting method, face-face distance, covering area, etc.

In the case of valve, Flexible hose, Expansion joint, etc., please present drawing of them including connecting method, face-face distance, covering area, etc. If you need optional components for installation, we will offer necessary components and qty. of them.

If you need optional components for installation, we will offer necessary components and qty. of them. If there are many installation positions, please present piping drawing and relative documents.

If there are many installation positions, please present piping drawing and relative documents. Considering location for installation, inside liquids, etc., please select material type, A or B.

Considering location for installation, inside liquids, etc., please select material type, A or B.

For quotation or order of Green Cover, please download a form, Request form for quotation or order. After fill it, please sent the form, Facsimile : +81-(0)3-3256-7827 or E-mail : info@green-tnj.co.jp.

Down load : Green Cover Request form for quotation or order >

※左記をクリックし

同書類をダウンロード

Procedure of quotation request or order

Please let us know the following subjects for quotation or order

①Connection spec. of piping : Flange, Butt welding, Socket, Thread socket, Ferrule, Clamp, etc.

②Pipe spec. : Size and material ( Metal, Resin, With lining etc.)

③In the case of covered with insulator, please let us know outside dimensions of the insulator.

In the case of valve, Flexible hose, Expansion joint, etc., please present drawings of them including connecting method, face-face distance, covering area, etc.

In the case of valve, Flexible hose, Expansion joint, etc., please present drawings of them including connecting method, face-face distance, covering area, etc.

If you need optional components for installation, we will offer necessary components and qty. of them.

If you need optional components for installation, we will offer necessary components and qty. of them. If there are many installation positions, please present piping drawings and relative documents.

If there are many installation positions, please present piping drawings and relative documents. Considering location for installation, inside liquids, etc., please select material type A or B.

Considering location for installation, inside liquids, etc., please select material type A or B.

For quotation or order of Green Cover, please download a form, Questionnaire of Green Cover

After fill it, please sent the form, Facsimile : +81-(0)3-3256-7827 or E-mail : info@green-tnj.co.jp.