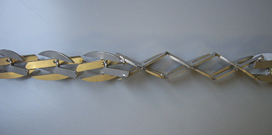

New Static Mixer consists of regularly assembled integral blade pieces, developed with our individual conception. Pressurized liquids are continuously and effectively divided, decentralized, mixed, and agitated through the mixer.

This mixer also make temperature, concentration, and flow speed uniformed and can finally realize high reliable mixing.

Advantage

HIGH PERFORMANCE

- ① Integral blade structure realize effective and necessary mixing in shorter mixer length.

- ② Since mixing process is not exposed to outside air, there are not deterioration of fluid quality and possibility of ignition and explosion.

- ③ We offer suitable conditions such as angle of blade, number of blades, material, etc. due to liquids and operation conditions.

LOW PRICE

- ① Integral module unit can realize reduction of cost on manufacturing.

- ② Due to the highly efficient mixing, length of the mixer become shorter. Finally total cost will be reduced.

- ③ Any power sources for mixing are not needed. Then installation works such as wiring are not also needed and total running cost will be reduced.

MAINTENANCE

- ① There are not any workings for mixing such as rotation, operation , sliding etc. Any maintenances such as changes of components are not also needed. (Except for cases of abrasions to mixing blades in long operation.)

- ② Removal of mixing unit from housing pipe is available. Then it is easy to clean the unit. (Except for model that mixing unit is welded to the housing pipe.)

Application sample

1.Gas and gas

Mixing different types of gases and acceleration of reaction

2.Some kinds of Liquids

- ① Dilution, neutralization, and adjustment of quality and viscosity,

- ② Adjustment of water quality and hardness, and aeration

3.Liquid and air

- ① Mixing, reaction, dissolution, and aeration of liquid, and air or gas.

- ② Gas cleaning and aeration of active sludge

- ③ Deaerator of dissolved gas by mixing

4.Liquid and solid

Dispersion or uniform of solid or powder to liquid

5.Heating and cooling

Heating and cooling of gas and liquid by improving heat conductivity

Model

We chose suitable model from following model due to purpose of mixing. We prepare special model upon requests.

WB

WB model is our basic model covering almost all mixing. Compared with our former model, resistance of flow direction is low and pressure drop is also reduced in mixing middle and high viscosity liquids.

XL

Basic performance of XL model is the same as XB mode. This model is adopted to bigger mixer, basically 10” or more.

Due to adaption this model, we can shorten length of mixer.

XB

In order to improve heating or cooling conductivity, this model is inserted to heat exchanger.

Application samples

L…Liquid S…Steam A…Air

a…Additive G…Gas C…Coolant

Selection of spec.

Considering purpose of mixing, characteristics of fluids, pipi size and connection means, etc., we offer suitable spec.

1.Length of mixer (Number of elements)

Length of mixer is decided with characteristics of fluids and flowing condition.

- ①Due to flow rate, density, and viscosity of mixing fluids, we calculate total flow rate, total density, and viscosity of mixed fluid,

- ②Schedule of pipe, housing pipe, is decided by pressure and temperature of operating or design.

- ③Total flow rate, kinematic viscosity, and Reynold’ number are calculated by designated pipi size and the above calculation results.

Due to flowing condition, necessary number of elements is decided based on our experimental value.

In the case of laminar flow and bigger difference of flowing rate between (among) flow rates, more necessary number of elements is needed. This means length of mixer is longer..

※Element means minimum unit of mixer, which assembled a pair of blades. The units are assembled as rotating 90 degree.

2.Pressure Drop

Pressure drop is calculated by the following formula.

① Turbulent flow

△P = (Ne・ρ・v2)・N/1000 kPa

② Laminar flow

△P = (Ne・μ・v/d)・N/1000 kPa

Note :

(1) Ne:Constant on flowing condition

(2) ρ:Density of mixed fluids(kg/m3)

(3) v :Flow rate of mixed fluids(m/s)

(4) N :Number of elements

(5) μ:Viscosity of mixed fluids (Pa・sec.)

(6) d :Inside diameter of housing pipe(m)

2.Selection of specification

- ①After the above calculation, we decide size of housing pipe. the pipe, class, designated connection, material, etc.

- ②Connection, material, surface finish are as follow ;

- (1) Connection:Our standard is JIS flange. We accept other connection such as ASME flange, ferrule, Socket, etc.

- (2) Material:Our standard is SUS304. SUS304L, SUS316L, Titanium, Hastelloy, etc. are available

- (3) Surface finish:Our standard is acid pickling. Electrolytic polishing is available.

Request of quotation

Due to the above steps, we offer specification of mixer. If you have any questions, please feel free to contact us.

As to any inquiry on New Static Mixer, please download a form and sent to us via facsimile +81-(0)3-3256-7827 or E-mail info@green-tnj.co.jp after filling in the form.